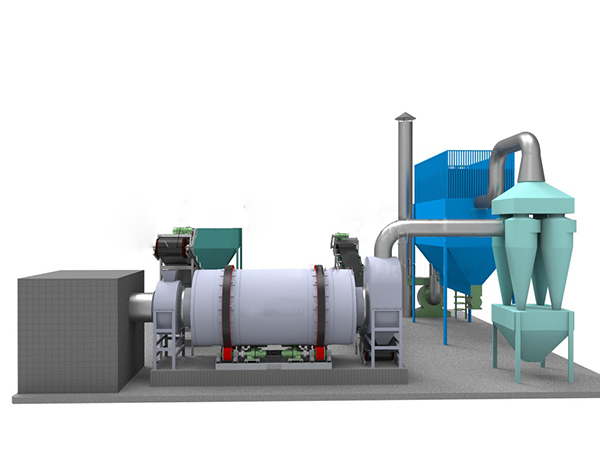

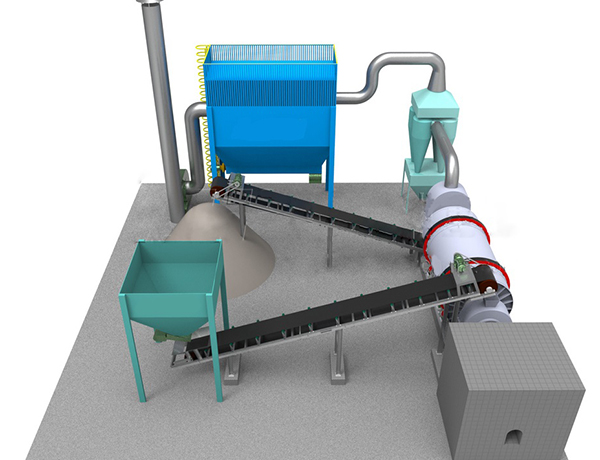

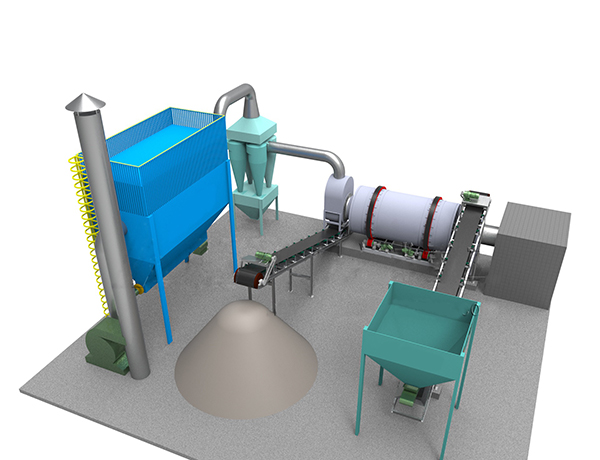

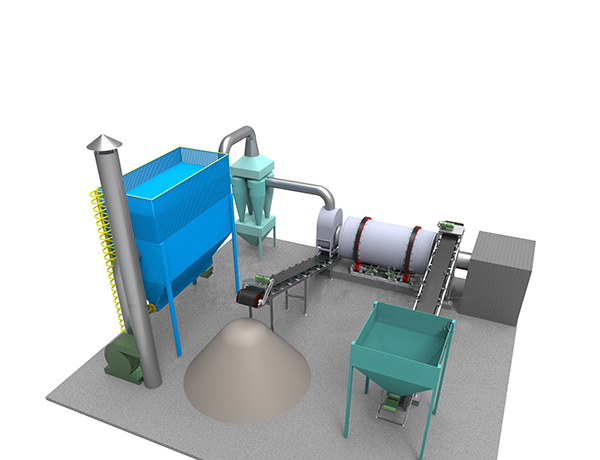

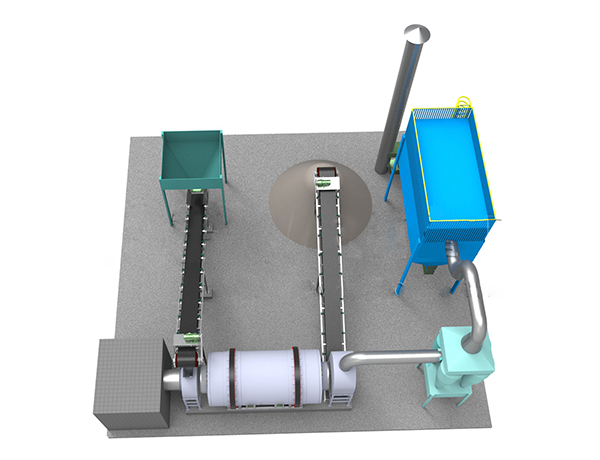

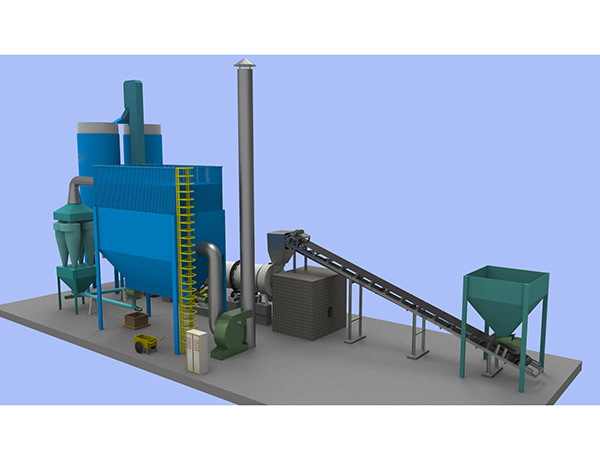

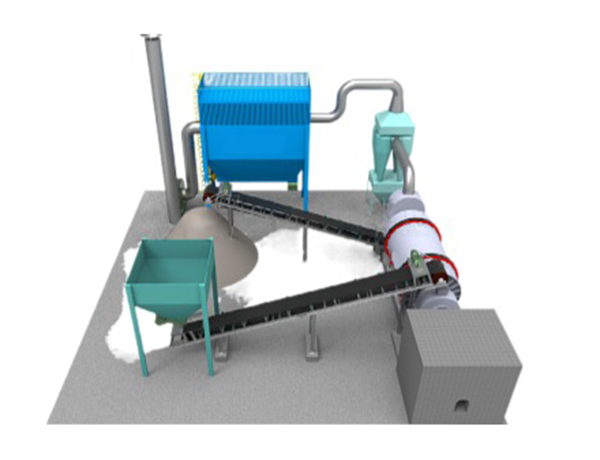

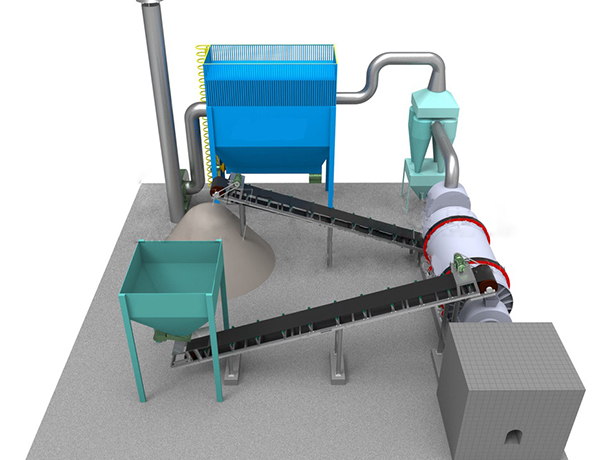

Granular Material Drying System

Granular Material Drying System

Qhov zoo ntawm qhov system

High thermal efficiency

Thaum tshav kub kub preservation cov ntaub ntawv uas muaj kub tsis kam, ua ke nrog feature ntawm lub tshav kub kev siv ntawm peb-lub tog raj kheej tshuab ziab khaub ncaws, lub zog txuag nyhuv yog pom tseeb.

Cov cuab yeej siv qis qis

Cov khoom siv kub yog <50 ℃, uas tuaj yeem nkag ncaj qha mus rau hauv cov khoom warehouse, thiab cov khoom cua txias tsis tas yuav tsum tau;Tail gas kub yog qhov tsawg, cov khoom siv tshem tawm plua plav yog nrog lub neej ua haujlwm ntev.

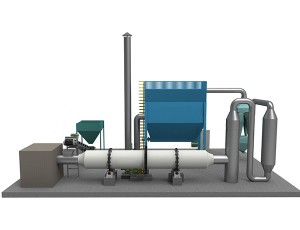

Qhov chaw me me hauv av, yooj yim rau nruab

Nws qhov chaw npog yog 50% tsawg dua li ntawm ib lub tog raj kheej tshuab ziab khaub ncaws, kev tsim kho kev nqis peev txo los ntawm 50% thiab kev siv hluav taws xob txo los ntawm 60%, qhov txheej txheem ziab ziab yog compact nrog cov txheej txheem yooj yim ntws.

Txoj Cai Ua Haujlwm

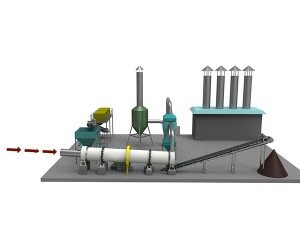

Cov khoom yog pub rau hauv kiln txawm tias kawg ntawm kiln (siab dua ntawm lub tog raj kheej).Vim tias lub tog raj kheej yog inclined thiab nws tig maj mam, cov khoom txav nrog lub voj voog nrog rau cov kev taw qhia axial (los ntawm sab siab mus rau sab qis).Tom qab dhau los ntawm kev hloov pauv ntawm lub cev thiab tshuaj, cov khoom nkag mus rau hauv lub tshuab txias los ntawm lub taub hau ntawm qhov cub tom qab ua tiav calcination.Roj yog pub rau hauv lub taub hau kiln los ntawm lub taub hau kiln, thiab cov pa roj yuav tawm ntawm qhov kawg ntawm qhov cub tom qab sib pauv cov khoom cua sov.

Technical Parameters ntawm peb lub tog raj kheej tshuab ziab khaub ncaws

| Qauv | Cov ntaub ntawv lub tog raj kheej | Muaj peev xwm (t / h) | Lub tog raj kheej rotary ceev (r/min) | Hwj chim (kW) | ||||

| Sab nraud lub tog raj kheej txoj kab uas hla (m) | Sab nrauv lub tog raj kheej ntev (m) | Lub tog raj kheej ntim (m3) | Dej xuab zeb | ya tshauv | Slag | |||

| wb 6203 | 1.6 | 1.8 | 3.6 | 2-3 | 1-2 | 1-2 | 3-10 | 4 |

| wb 6205 | 2 | 2 | 6.28 ib | 4-5 | 2-3 | 3-4 | 3-10 | 5.5 |

| wb 6210 | 2.2 | 2.5 | 9.5 ib | 8-10 | 4-5 | 6-8 | 3-10 | 7.5 |

| wb 6215 | 2.5 | 2.8 | 13.7 ib | 12-15 | 7–8 | 10-12 | 3-10 | 11 |

| VS2 × 4 | 2 | 4 | 12.56 Nws | 8–12 | 4-6 | 8-10 | 3-10 | 3 × 2 |

| VS2 × 5 | 2 | 5 | 15.7 ib | 12-15 | 6-7 | 10-13 | 3-10 | 4 × 2 |

| VS2 × 6 | 2 | 6 | 18.84 Nws | 20-25 | 10-17 | 20-27 | 3-10 | 7.5 × 2 |

| VS 2.2 × 4.5 | 2.2 | 4.5 | 17.09 Nws | 14-18 | 7–9 | 12-15 | 3-10 | 5.5 × 2 |

| VS 2.5 × 6 | 2.5 | 6.5 | 31.89 Nws | 23-28 | 10-13 | 20-22 | 3-10 | 5.5 × 4 |

| 2.7 × 7 | 2.7 | 7 | 40.5 ib | 30-35 : kuv | 20-25 | 27-45 : kuv | 3-10 | 7.5 × 4 |

| 2.8 × 6 | 2.8 | 6 | 36.9 ua | 30-35 : kuv | 15-18 | 25-30 | 3-10 | 5.5 × 4 |

| VS3 × 6 | 3 | 6 | 42.39 Nws | 35-40 : kuv | 18-20 | 32-35 : kuv | 3-10 | 7.5 × 4 |

| 3 x 7 | 3 | 7 | 49.46 ib | 40-45 : kuv | 20-25 | 35-40 : kuv | 3-10 | 7.5 × 4 |

| VS 3.2 × 7 | 3.2 | 7 | 56.26 ib | 45-50 | 25-30 | 40-45 : kuv | 3-10 | 11 × 4 |

| VS 3.2 × 8 | 3.2 | 8 | 64.3 ib | 50-55 | 30-35 : kuv | 45-50 | 3-10 | 11 × 4 |

| 3.6 × 8 | 3.6 | 8 | 81.38 ib | 60-70 ib | 35-40 : kuv | 60-65 | 3-10 | 15 × 4 |

| 3.8 × 9 | 3.8 | 9 | 102 | 70-80 ib | 40-45 : kuv | 70-75 ib | 3-10 | 15 × 4 |

| VS4 × 10 | 4 | 10 | 125.6 ib | 90-100 ib | 45-50 | 80-90 : kuv | 3-10 | 18.5 × 4 |

| VS 4.2 × 8.5 | 4.2 | 8.5 | 117.7 ib | 80-100 | 45-60 : kuv | 80-90 : kuv | 3-10 | 18.5 × 4 |

Cov khoom qhuav